Esterification of high-FFA feedstock for chemical biodiesel plants

Processing high-FFA feedstocks with acid esterification pretreatment requires a high acid dosage, long reaction times, and significant CAPEX expense to combat corrosion.

Boost profits by processing high-FFA feedstock in your existing asset

Like many biodiesel plant operators, you’re looking to start processing high-FFA feedstocks at the lowest possible capital cost. To accomplish this, many producers build acid esterification pre-treatment to process feedstocks in their existing chemical transesterification plants. However, acid esterification for high-FFA feedstocks requires a high acid dosage, long reaction times, and significant CAPEX expenditures to combat corrosion.

You can overcome these challenges and start processing high-FFA feedstocks prior to transesterification at a low cost and with minimal CAPEX with enzymatic esterification.

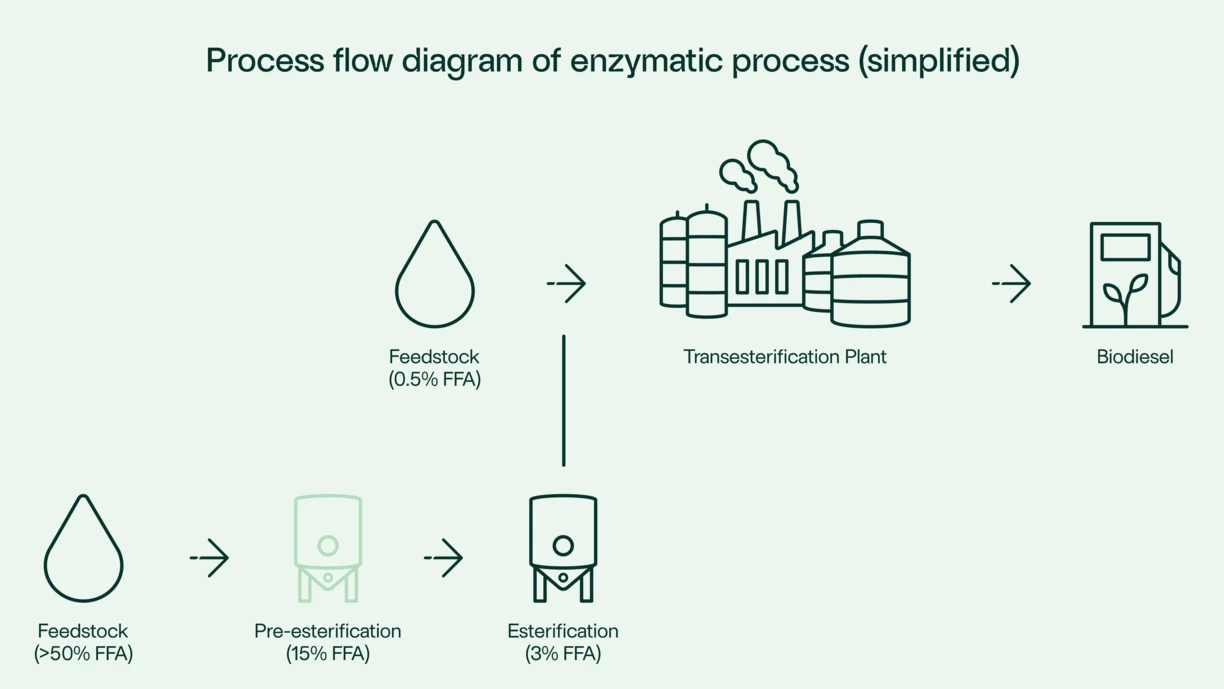

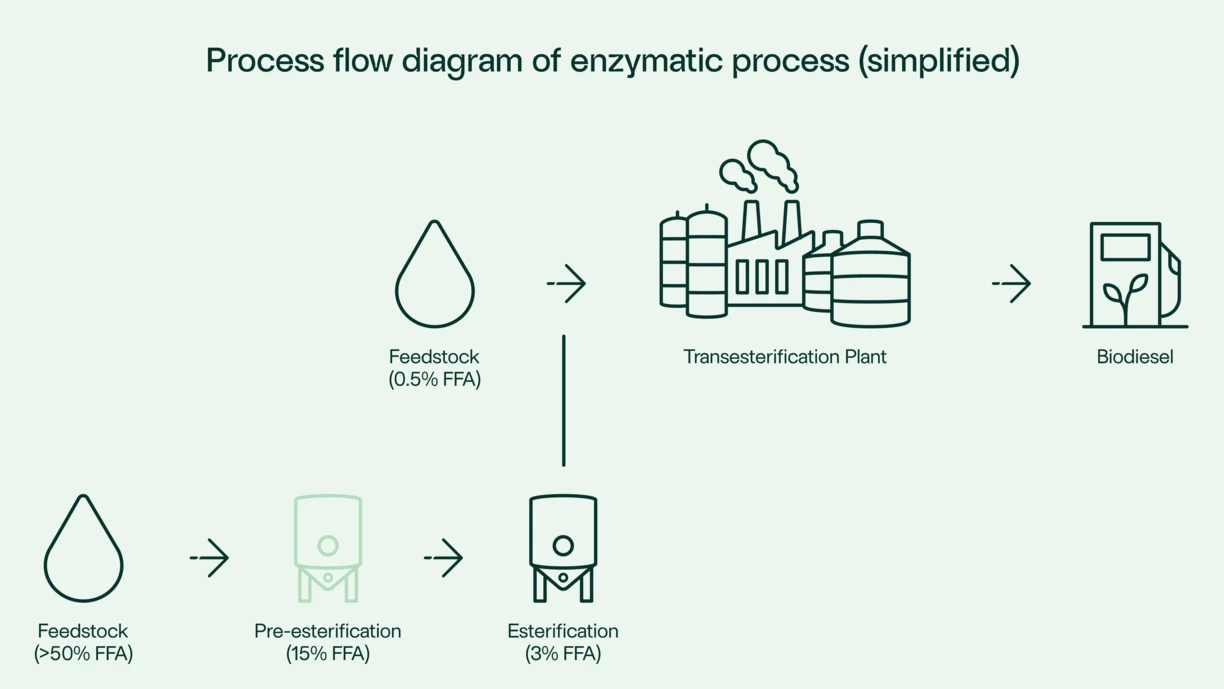

In this process, high FFA feedstocks are pretreated with Eversa® Transform 2.0 and then co-processed with chemical transesterification for on-spec biodiesel. Eversa® Transform 2.0 is well-proven to convert feedstocks with up to 90% FFA, such as fatty acid distillate, to crude FAME with 3-5% FFA.

Feedstock-specific pretreatment is accomplished using multiple bolt-on continuous stirred-tank reactors (CSTR) for a 150 TDP plant at ambient pressure and temperature, and delivers a number of benefits:

- Up to €4.0 million more profit per year from high-FFA feedstocks

- CAPEX as low as €2.0 million

- A no-risk, bolt-on solution with no plant downtime

With our FlexFit® process, Novonesis engineers can help you identify the best ways for your plant to maximize profits and transition to feedstock flexibility with our Eversa® Transform 2.0 biocatalyst.

Learn more about Novonesis enzymatic biodiesel refining routes:

Upgrade oleins in your chemical biodiesel plant

Biodiesel from distillates

Biodiesel from high-FFA feedstocks

Esterification of high-FFA feedstock for chemical biodiesel plants

Learn more about Novonesis enzymatic biodiesel refining routes:

Want to know more? Contact our biodiesel experts today.

Fill in the form and one of our biodiesel experts will be in touch.

One more step…

To complete the get in touch form or sign up, please click on the button below to enable cookies.