Upgrade oleins in your chemical biodiesel plant

Eversa® Transform 2.0 increases yield by converting oleins from chemical biodiesel to crude FAME (3-5% FFA) which is recirculated back to the chemical biodiesel process to deliver on-spec biodiesel of less than 0.25% FFA.

Boost profits and lower CAPEX with our no-risk, bolt-on solution

Biodiesel plants using rapeseed, palm, or soybean oil feedstocks typically lose up to 5% in the form of soap stock. This soap stock is typically either sold at a considerable discount or converted to FAME biodiesel via acid esterification. Acid esterification creates a number of disadvantages, including the creation of challenging byproducts, an unappealing black color, and dimethyl ether.

Additionally, corrosion from acid esterification can create a high CAPEX.

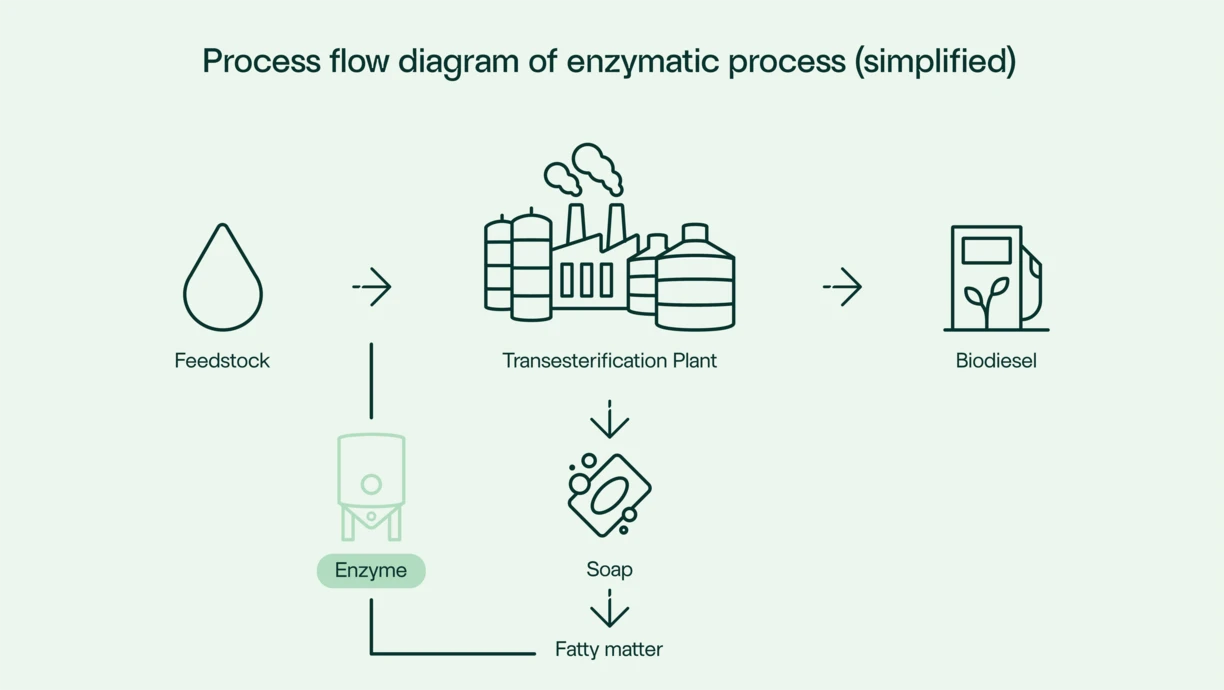

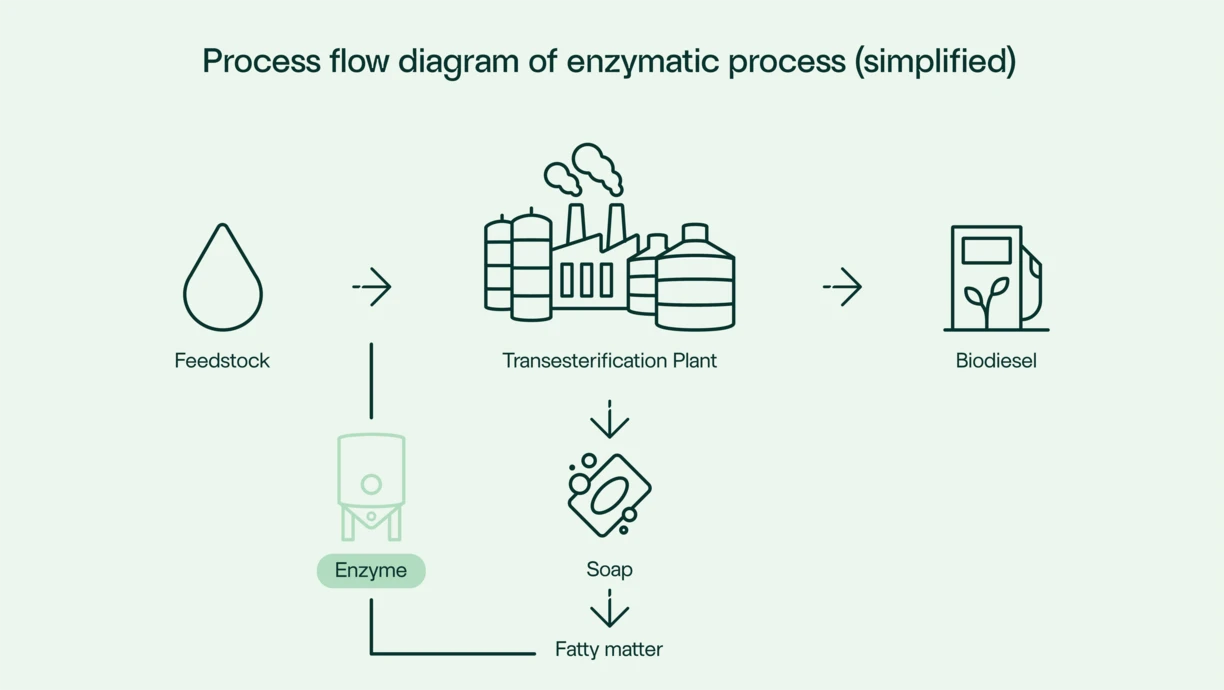

Using enzymatic technology, you can boost your profit by upgrading your oleins to biodiesel. Eversa® Transform 2.0 increases yield by converting oleins from chemical biodiesel to crude FAME, which is recirculated back to the chemical biodiesel process to deliver on-spec biodiesel of less than 0.25% FFA. Eversa® Transform 2.0 has been proven to convert oleins to crude FAME (3-5% FFA).

This bolt-on solution with a batch reactor at ambient temperature and pressure produces significant results:

- Up to €1.0 million additional profit per year from

- CAPEX as low as €0.5 million

- Bolt-on solution poses no risk of plant down-time

Additionally, plants with integrated degumming of soy and rapeseed oil and biodiesel production can maximize profits using enzymatic degumming . The process takes glycerol from chemical transesterification to saponify FFAs in enzymatically degummed vegetable oil going into chemical transesterification.

With our FlexFit® process, Novonesis engineers can help you identify the best ways for your plant to maximize profits and transition to feedstock flexibility with our Eversa® Transform 2.0 biocatalyst.

Learn more about Novonesis enzymatic biodiesel refining routes:

Want to know more? Contact our biodiesel experts today.

Fill in the form and one of our biodiesel experts will be in touch.

One more step…

To complete the get in touch form or sign up, please click on the button below to enable cookies.